by Victoria Hilton

A factory with a difference, Terumo Aortic handcrafts the “tubes of life” which sustain 5,600 000+ (and counting) patients across the world. Originally conceived in 1921 as a thermometer manufacturer, Terumo Corporation has evolved to become a global leader in the creation of medical devices, including those for people with aortic and peripheral vascular disease. Eileen Novins from the Marfan Foundation invited me to join her on a tour of this fascinating factory where patients’ faces adorn the walls, reminding employees that every working day, they are saving someone’s life.

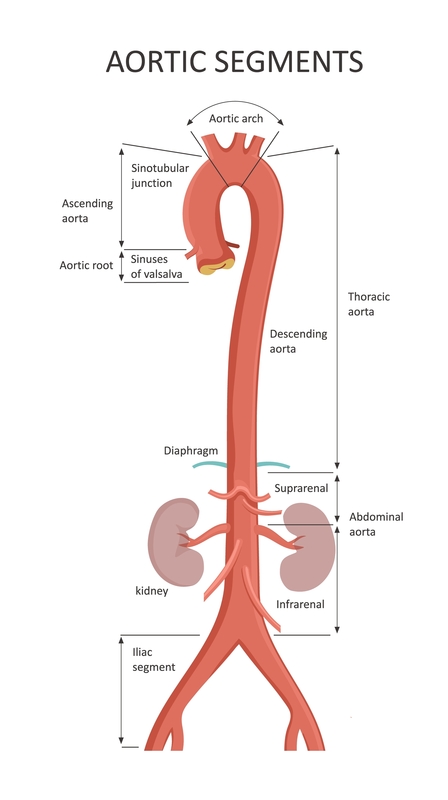

The tour was a revelation! Chief Commercial Officer Tarik Pacuka greeted us and whisked us through the decades, as Terumo expanded its products and locations, from making thermometers in Japan to creating disposable syringes and blood bags, before launching the world’s first microporous hollow-fibre membrane oxygenator (a device used during heart bypass surgery to exchange gases, oxygenating the blood and removing carbon dioxide) in 1982, marking a significant development for the new cardiovascular arm of the business. This recently formed cardiovascular enterprise is now split into three divisions, of which Terumo Aortic is the fastest growing. Underpinned by a relentless drive for quality and a continuity of dedicated staff, Terumo Aortic produces an endlessly evolving, comprehensive range of endovascular, hybrid, aortic root replacement and custom devices to treat both ascending and descending aneurysms, amongst other aortic conditions. And the “consumer” is the clinician.

[Pictured from l to r: Erik Pomp (Chief Executive Officer, Terumo Aortic; Victoria Hilton (Marfan Trust), Eileen Novins (Marfan Foundation); Tarik Pacuka (Chief Commercial Officer, Terumo Aortic).

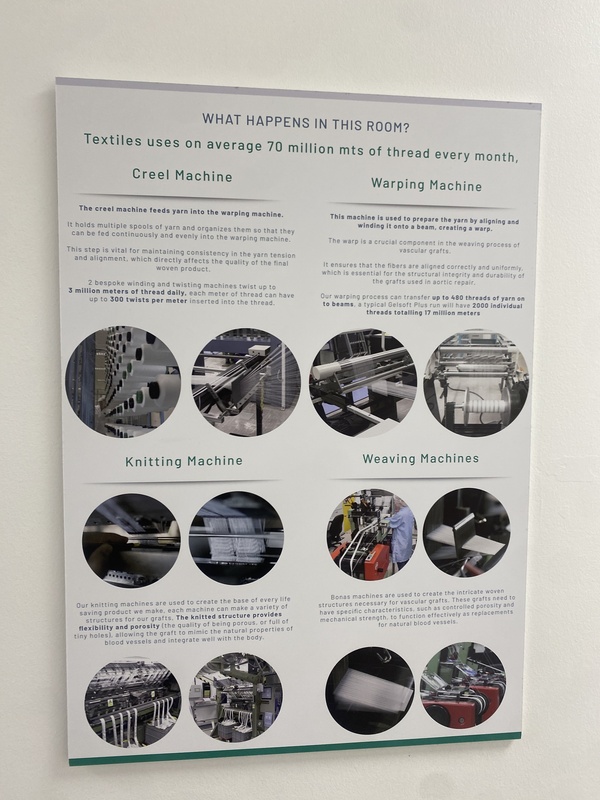

It starts with a thread! From a single thread grows a portfolio of life-saving devices. Our tour took us down long corridors off which lie vast rooms, each filled with a different and distinct area of expertise. The product begins life in the Textiles Room, a cavernous space occupied by enormous beams of yarn, the strands of which are finer than a human hair. Painstakingly fed by hand into various machines, the yarn is wound, twisted, and warped, before being moved on to the knitting or weaving machines, creating a flat fabric to be turned into a tubular graft.

[pictured: Terumo employee in the Textiles Room]

Fun Facts:

Knitted material allows for pliability and porosity. It means the graft can mimic the natural properties of the blood vessels and integrate with the body.

Woven material is used for vascular grafts. These grafts need to have controlled porosity and mechanical strength, to function effectively as replacements for natural blood vessels.

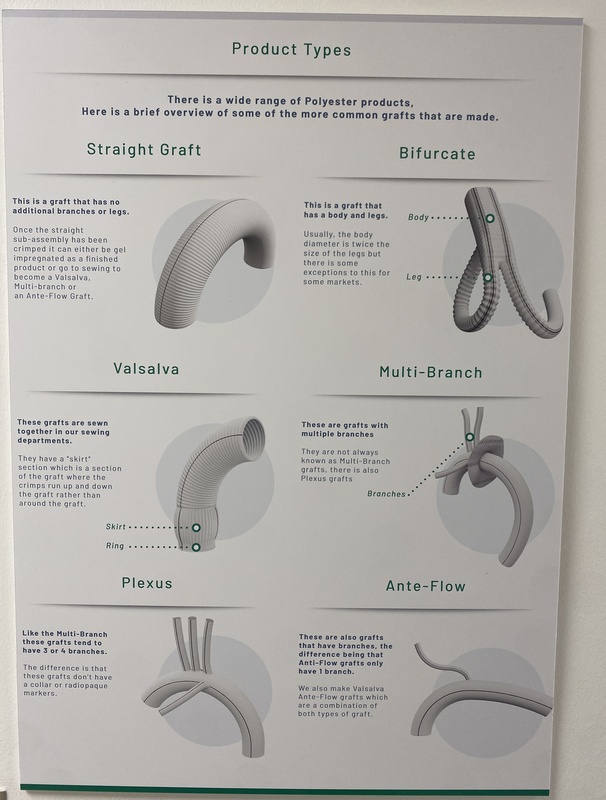

From Textiles to Polyester, the product has reached stage 2 of its creation where the flat fabric is washed, crimped, heated, and hand-sewn into a graft. (Crimping ensures the graft expands once it reaches its target site; heat setting stabilises the shape and structure of the material). To facilitate X-rays, metal rings are sewn into the fabric.

[Pictured: The Terumo Surgical Grafts Cleanroom]

Its next step depends on its ultimate purpose – a straight graft for a thoracic aorc aneurysm for example, or something more intricate and complicated such as a Gelweave Valsalva for aortic root replacement procedures, in which case it is sent to Sewing for “Extras”. The Valsalva device wears a "skirt"!

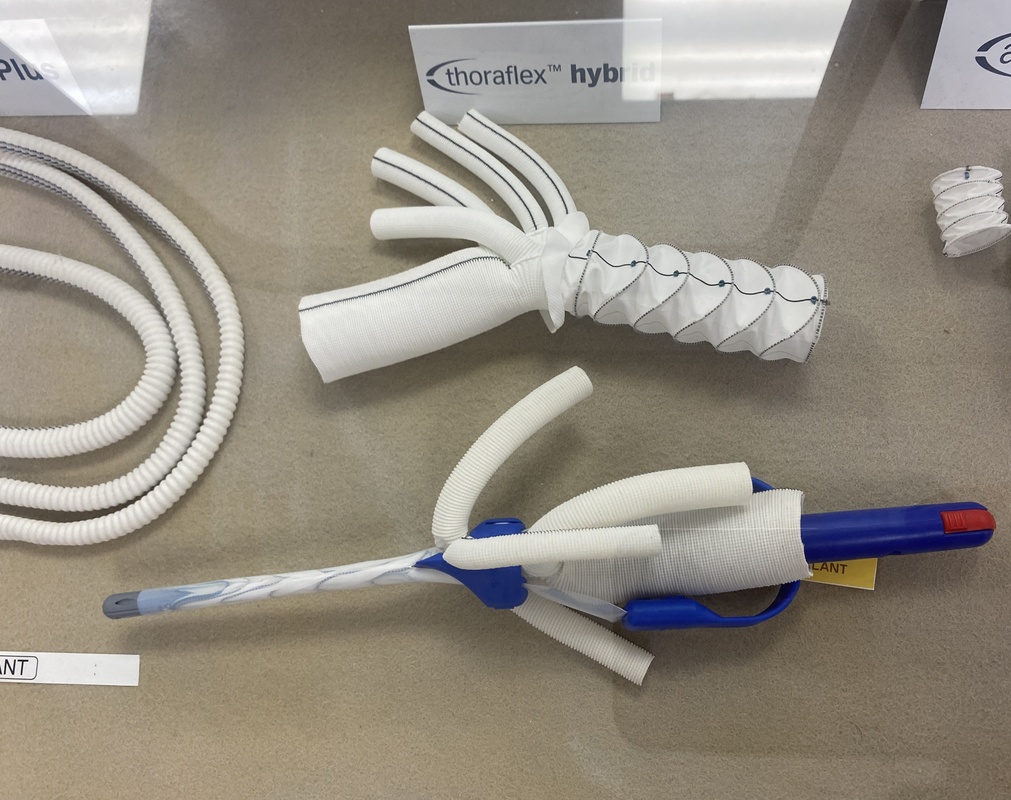

Sporting blue spacesuits and stripped of make-up and jewellery (scary), Eileen and I were ushered into the Hybrid Thoraflex™ Sewing Room where magic happens. First approved in 2012, the Thoraflex™ Hybrid device is designed for the open surgical repair of aneurysms and/or dissections in the aortic arch and descending aorta. Pictured left, the four arch branches which facilitate the reconstruction of the major aortic branch vessels, emerge from manually made fenestrations and the tubes are then hand-sewn into place. The dexterity of the craftsmen was something to behold as they mimic mother nature with their creations.

Continuing the graft’s journey, we visited the delivery system department and watched as these blue contraptions, used by surgeons to release the implant into the patient’s body, were hand assembled. This is the penulmate step before gel-impregnation, sterilisation and packaging. Boxes are piled one on top of the other and distributed, breathing life across the world.

Thank you to Val, Laura, Tarik, Erik, Kevin, Colin, Sharon, Ian and Robert for an unforgettable journey!

Mind the Aorta!

Further Fun Facts

• Terumo was founded in Japan by a group of sciensts led by Dr Shibasaburo Kitasato and named Sekisen Ken-onki Corporation which means Red Line Thermometer.

• Terumo Aortic creates 1,000 products a day and 150,000 grafts a year.

• From inception to completion, the medical devices take on average three weeks to make.

• Every product goes through 300 touchpoints!

• Up to 3 million metres of thread is twisted every day.

• Terumo Aortic has plants in America, Vietnam and Japan, in addion to Glasgow.

• Fusing traditional open surgical techniques with minimally invasive endovascular approaches Terumo’s hybrid devices are designed to “outlive the patient”. The most recent addition to their range is the Thoracoflo. “Current techniques for thoraco-abdominal aortic repair are associated with serious complications and the problem of spinal cord ischaemia remains unsolved. The Thoracoflo device uses the frozen elephant trunk principle. By avoiding a thoracotomy and extracorporeal circulation it is associated with reduced trauma to the patient”.